ACT REPAIR SERVICES

Servo Motor Repair

We are a dedicated Servo Motor Department.

Here at ACT, our technicians are artfully trained to diagnose and repair each servo motor using proprietary techniques; this ensures the proper operation of the motor according to the manufacturer’s specifications. Each motor goes through a thorough testing procedure to determine the motor malfunction. This entails a complete teardown, repair, and post-test to bring the motor operation up to proper specs. Each repair will also include a complete evaluation report outlining the motor’s condition upon arrival, with motor tests performed to determine the condition of the rotor magnets, stator windings, and bearings.

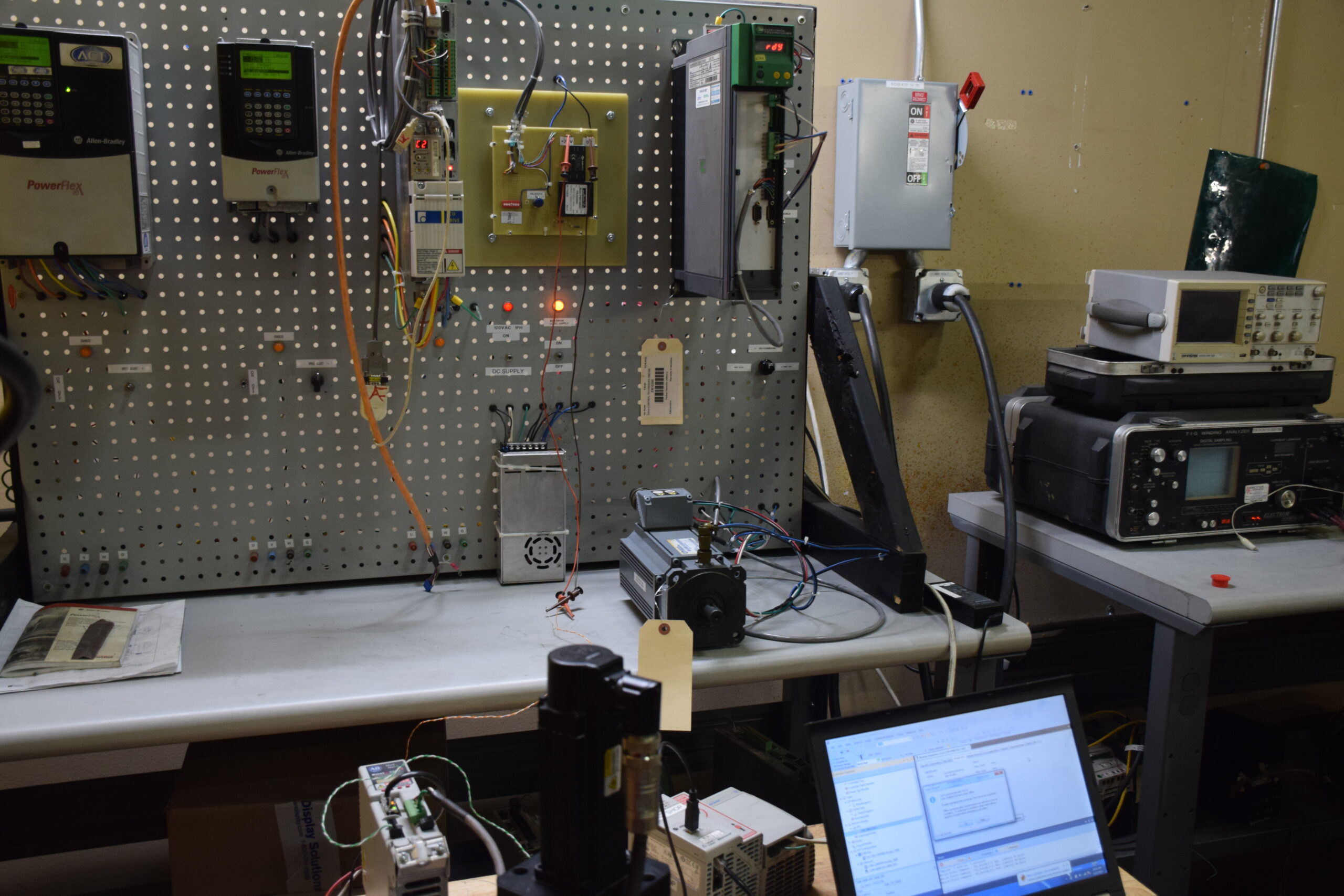

Winding tests are performed using the PdMA hardware and software tools. Motor CEMF and brake torque is also tested and compared with known data. The feedback device is tested using proprietary Mitchell hardware and software equipment to evaluate the feedback device(s) condition. The results of those tests, any pertinent datasheets, and daily job notes pertinent to the repair will be included with the repair.

IN-DEPTH TESTING PROCESS

- We utilize the Mitchell Equipment diagnostic and repair system

- Initial back-drive testing alignment verification

- Verify breakdown condition under “real life” full load conditions

- Record test data including winding waveforms, feedback signals, reverse generated voltage readings, shaft, and encoder alignment data

QUALITY REPAIR METHOD

- All bearings are replaced with NEW bearings

- We verify feedback devices to OEM specification

- In-house machining center that can re-machine the end bells, shaft, and motor housings

Our Servo Motor Repair Process

- Check-In Process:

Upon arrival at the repair facility, the servo motor is checked in through a systematic process. This involves documenting the motor’s make, model, and any visible damage or issues. The customer provides details about the motor’s performance problems and any relevant operational history. A unique identifier or work order number is assigned for tracking purposes.

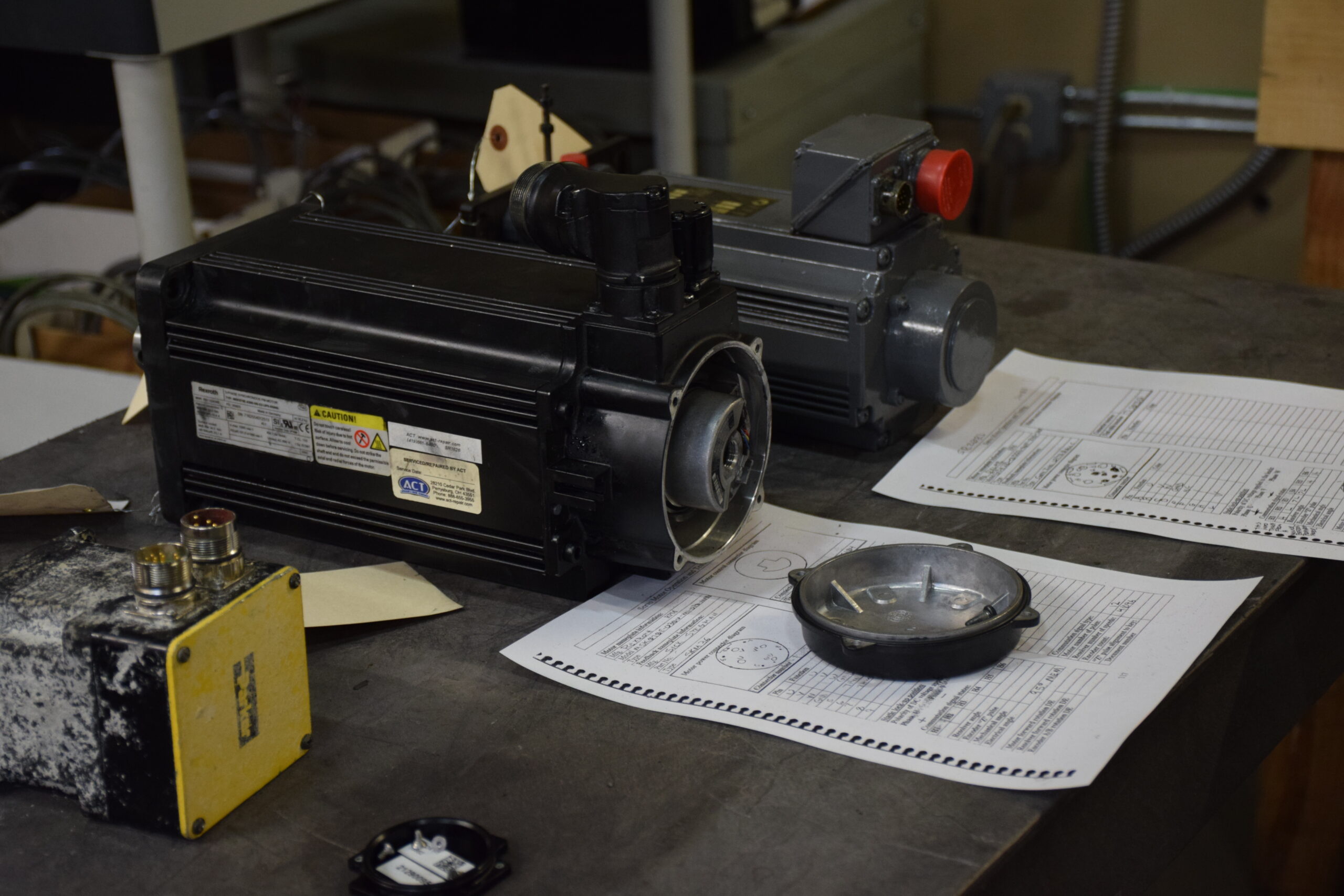

- Evaluation:

Skilled technicians conduct a thorough evaluation of the servo motor to identify the root cause of the malfunction. This assessment includes a detailed inspection of the internal components, such as the encoder, bearings, and wiring. Specialized diagnostic tools may be used to measure electrical and mechanical parameters, helping to pinpoint the specific areas that require attention.

- Quote:

Following the evaluation, a comprehensive quote is prepared for the customer. This quote outlines the cost of the necessary repairs, including parts and labor. The customer is then provided with a detailed breakdown of the identified issues, allowing them to make an informed decision on whether to proceed with the repairs. Any additional recommendations for preventive maintenance may also be included in the quote.

- Repair:

Once the customer approves the quote, the repair process begins. Skilled technicians disassemble the servo motor, replacing faulty components such as damaged wires, bearings, or electronic modules. Careful attention is paid to ensure that the motor is reassembled according to manufacturer specifications. Quality replacement parts are used to restore the motor to optimal functionality. Technicians also address any other issues discovered during the repair process.

- Testing:

After the repairs are completed, the servo motor undergoes rigorous testing to ensure it meets or exceeds the manufacturer’s specifications. This testing involves verifying the motor’s electrical and mechanical performance, checking for proper alignment, and validating the functionality of any integrated feedback systems. Only when the motor passes these tests is it deemed ready for return to the customer.

- Return to You:

The repaired servo motor is carefully packaged and shipped back to the customer. The return process includes providing the customer with relevant documentation, such as test reports and a summary of the performed repairs. The customer is also informed of any preventive maintenance recommendations to prolong the lifespan of the servo motor. Additionally, tracking information is provided to enable the customer to monitor the return shipment.

Full motor testing capabilities with balance & rewind done in-house.

Download Servo Motor Line Card